Written by: Christin Zimmer – Product and Service Manager at Lignopure

Why is lignin not yet used in many products when there is a large amount available and it has a diverse variety of functionalities? The main issue is that a natural polymer never owns a consistent quality.

To illustrate it figuratively, there is more than one adhesive or glue kind in the market; for paper, wood, glass, metal, ceramic, different colors, etc. Lignin is among other things, the glue that keeps many plants’ structures together, and as in the previous example, each lignin is indistinctly different based on its molecular structure which is given by its plant of origin. This complicates greatly the fully valorisation of this amazing natural polymer.

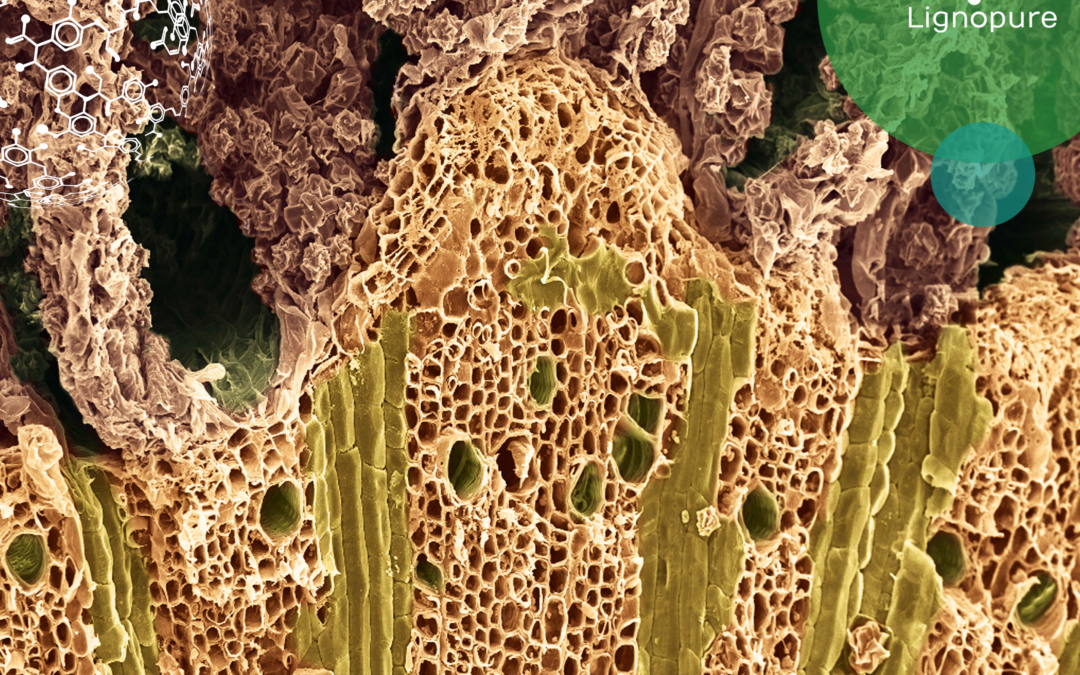

Lignin structure

The complex three-dimensional lignin polymer consists of three main precursors p-coumaryl alcohol, coniferyl alcohol and sinapyl alcohol. Depending on the abundance of different groups of vascular plants, plant tissues and cell-wall layers, the number of present aromatic constituents: p-hydroxyphenyl (H), guaiacyl (G) and syringyl (S) units is individual for every plant’s lignin.

Another variation factor is each lignin molecular weight, based on the cross-linkage of the lignin polymer during the lignification process. A third variable for the structural diversity of lignin is the functional groups and their quantity: hydroxyl, methoxyl, carbonyl and carboxyl groups.

These beforementioned structural differences give already an initial indication of how many variants of lignin can be found. To this, it has to be added the fact that the lignin structure suffers changes during the growth of its plant of origin. Finally, lignin’s functional groups are based on the raw material (or source) and these are affected by the different extraction or isolation methods used in different industries like biorefineries and pulp and carton manufacturers.

Lignopure’s know-how and solutions

Unquestionably, there are many factors that play a significant role in lignin characterization and valorization and this is the Lignopure team’s daily work and passion. – finding solutions and methods to benchmark lignin and creating necessary structures and processes to categorize the multitude of variables that lignin can have. Finding the similarities or differences between raw materials, extraction processes (and production parameters), physical properties, functionalities, etc.

Every result is leading to new insights and presents a bigger picture of the unique nature of lignin and its multiple possible applications.

References: